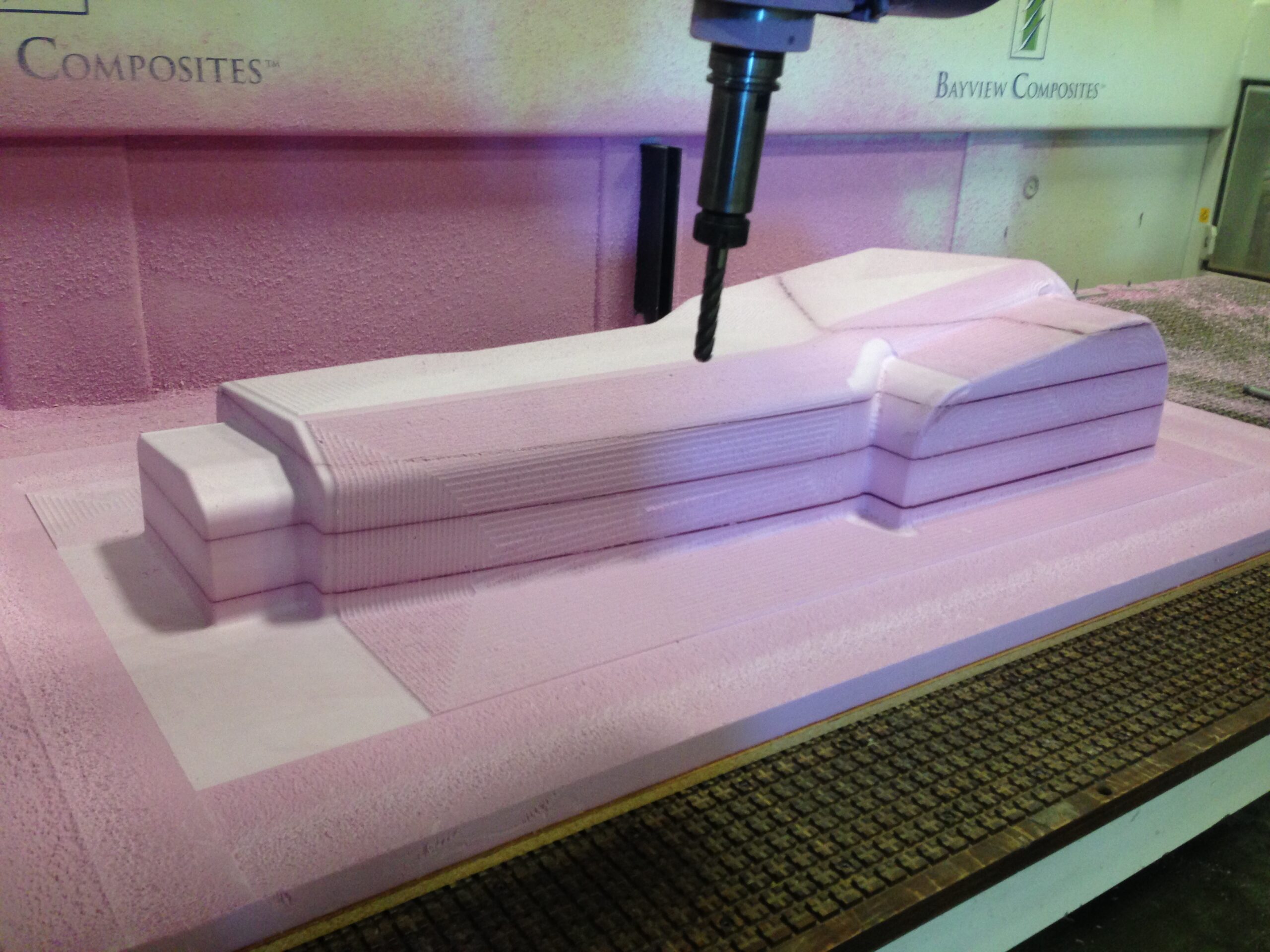

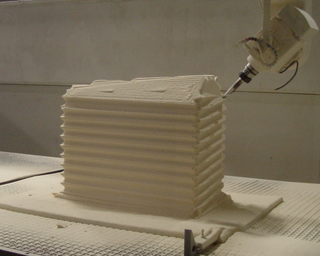

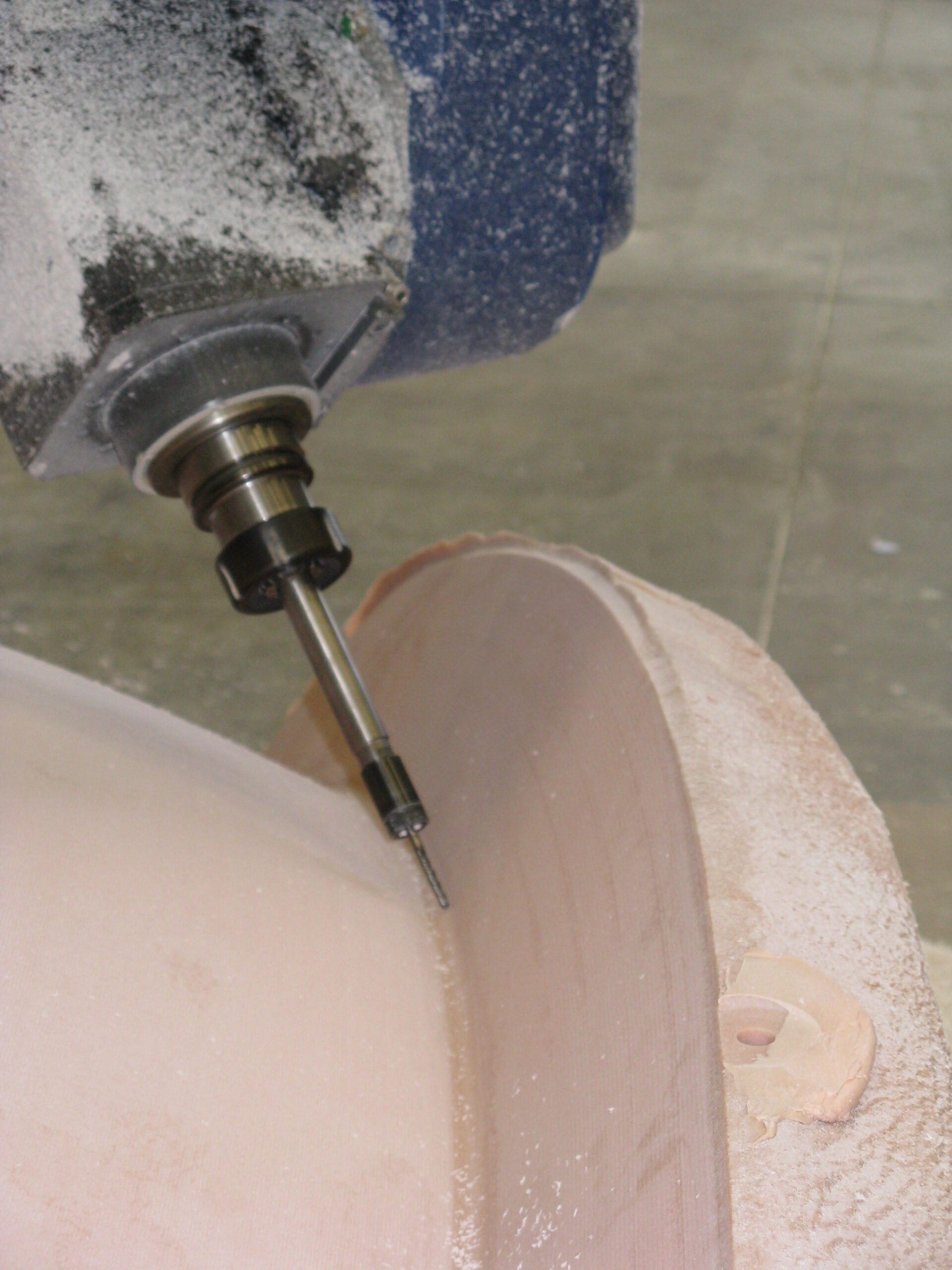

Patterns are manufactured in our 5-axis machining centers, which are laser tracked on a regular schedule to verify tolerances and ensure accuracy. BVC has two CNC 5-axis mills: our CMS Poseidon CNC, which has a working envelope of 83′ x 27′ x 13′ and our CMS Ares CNC, which has a working envelope of 16’x 6’x 4′. By utilizing CNC machining centers with large working envelopes, we are able to machine very large tools in a single setup, which reduces costly seams, increases accuracy, and reduces risk.

Molds and transfers can be produced off our CNC Patterns utilizing a variety of laminate processes including Open Mold/Hand-Lay-up, Wet bagging, Vacuum Infusion, and Prepreg OOA. BVC offers numerous construction methods allowing customers to optimize performance and cost relationships.

Pattern/Plug Features

- Dimensionally stable wood base structure

- Fiberglass composite reinforcement

- Polyester tooling paste machined surface

- Finishing and surface treatments to order

Pattern/Plug Materials

- High Temperature Epoxy Tooling Paste

- Polyurethane Foam Billet

- Polystyrene Foam Billet

- Plywood Cross Section Kits

- Medium Density Fiberboard (MDF)

Finishing

- High quality finishes available

- Industry leading surfacing materials

- Finish to specific grit levels

- RMS requirements are documented